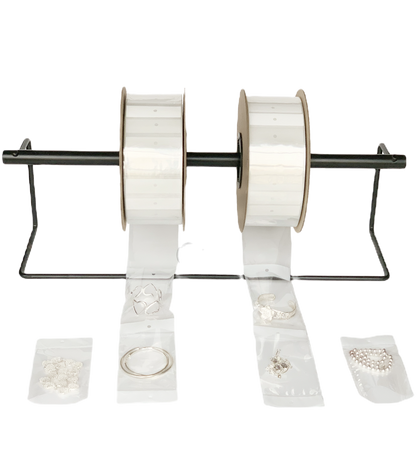

Accessory Auto‑Bagging

Pack small fashion accessories securely while keeping every SKU visible and easy to scan.

-

Right‑Sized for Accessories:no more wasting film on oversized bags.

-

See & Scan Instantly: Clear film keeps colors, sizes and barcodes visible without opening the bag.

-

Brand & Label Ready: Smooth, treated surfaces accept thermal‑transfer labels cleanly for fast e‑commerce processing.

-

Plug‑and‑Play on Auto‑Baggers: Runs on mainstream machines with standard cores and roll diameters—no extra setup changes.

Wide Industry Applications:

-

Apparel & Fashion Accessories: Belts, socks, hosiery, scarves, gloves, hats.

-

Jewelry & Hair Accessories: Necklaces, bracelets, earrings, clips, headbands.

-

Care & Spare Components: Spare buttons, repair kits, garment care accessories.

-

Subscription & Gift Programs: Curated accessory kits and small gift assortments.

Engineered for seamless integration with your existing auto-baggers. Our Accessory Auto‑Bagging rolls use standard 3" cores, optimized slip surfaces and precision‑matched perforation pitch to ensure smooth, zero‑jam feeding on mainstream apparel and e‑commerce bagging systems—without changing your current machine parameters.

-

Autobag®: AB 180, 500, 550 & 850S Series (Rolls)

-

Sharp™: SX™ & MAX-PRO™ Series (Rolls & Fan-Fold)

-

Pac Machinery™: Rollbag™ R1285 & R3200 Series (Rolls & Tubing)

E‑commerce Accessory Auto‑Bagging for Retail‑Ready Orders

What are Adsure® Accessory Auto‑Bags?

Precision‑engineered, pre‑opened bags on a roll sized specifically for small apparel accessories such as belts, socks, jewelry cards, care kits and spare components. Compact bag formats reduce void space in each pack, while high‑clarity film keeps size, color and style codes visible for fast picking and QA checks.

How to use our Accessory Auto‑Bagging ?

Drop‑in replacement for standard auto‑bags. Accessory bags are supplied as pre‑opened bags on rolls with matched core diameter and perforation pitch, so they can be loaded directly onto mainstream automatic baggers without changing machine settings. The smaller bag sizes and optimized slip surface allow operators to load small items quickly while maintaining clean seals and consistent print / thermal‑transfer label placement [Request a compatibility test roll] to validate fit with your specific machine model and production speed.

Specification

Mechanical Properties

Parameter | Specification Range | Test Method / Notes |

|---|---|---|

Material Base | LDPE / LLDPE mono or co‑extruded; optional recycled content | For high‑speed auto‑bagging, standard heat‑seal lines |

Appearance / Tint | Clear or light haze; optional white or tinted film | Retail and e‑commerce friendly display |

Film Thickness | 25–70 μm, tuned to product weight | Thickness controlled by internal QC |

Tensile Strength | Meets LDPE/LLDPE thin‑film tensile targets (MD/TD) | Tested per ASTM D882 |

Elongation at Break | High‑stretch film for feeding and loading | ASTM D882 thin film test |

Bag Style | Pre‑opened bags on roll; one end pre‑sealed with easy‑tear perforation | Suited for automatic separation and loading |

Size Range | Width 3–10 in; length 4–20 in; custom sizes | Matches accessory SKUs, auto loading |

Core & Roll Format | 3 in core; diameters fit mainstream auto‑baggers | Ready to run on most automatic baggers without modification |

Printability | Supports thermal transfer and flexo printing | Logos, sizes, barcodes, variable data |

Sustainability Options | Higher recycled content options available | Helps meet recyclability / ESG goals |

Option

Physical & Roll Dimensions

Parameter | Specification Range | Compatibility Notes |

|---|---|---|

Film Thickness | 1.0 mil – 2.75 mil (25–70 micron) | Balanced clarity and strength for small accessories on auto-bagging lines |

Bag Width (Opening) | 3" to 10" (75 mm – 250 mm) | Sized for jewelry, small leather goods, hair accessories and other small items |

Bag Length | 4" to 20" (100 mm – 510 mm) | Customizable to accessory dimensions and e-commerce pack-out needs |

Core Size (I.D.) | 3" (76 mm) industry standard | Matches most Autobagger and automatic bagging machine spindles |

Roll Outer Dia. (O.D.) | Up to 10" (254 mm) or custom | Optimized for long run-times on accessory auto-bagging systems without changeover |

Perforation Type | Horizontal (standard) or vertical, easy-tear | Horizontal for smooth machine feeding; vertical optional for end-user tear-open |

Venting Options | Optional micro-vents / pinhole vents | Releases trapped air to keep parcels compact and reduce shipping volume |

Euro Slot Position | Header zone, 15–20 mm from top seal | Positioned to avoid sealing bar while giving retail peg-hook compatibility |

Special Feature

-

Sustainable Material Options:

Available with higher recycled content or bio‑based films where required, helping brands reduce virgin plastic use and improve ESG metrics. -

Accessory‑Sized Bag Formats:

Compact pre‑opened bags on a roll are tailored for belts, socks, jewelry cards, care kits and other small items, reducing void space and film waste. -

High‑Clarity Identification:

Clear film makes colors, sizes and styles easy to verify at a glance, and supports barcode scanning through the bag without opening. -

Brand & Label Ready Surface:

Treated film surfaces accept flexographic printing and thermal‑transfer labels cleanly, keeping branding and SKU data sharp in fast e‑commerce workflows. -

Clean Feeding on Auto‑Baggers:

Optimized slip surface and precise perforations help bags feed smoothly through automatic baggers with minimal jams.

Structural Options

-

Size Range for Accessories:

Multiple standard widths and lengths for individual accessories or small kits, with custom sizes available for unique programs. -

Film & Tint Choices:

Clear or tinted PE films, with optional recycled‑content constructions to support sustainability goals. -

Perforation & Venting Styles:

Horizontal tear‑off perforations optimized for machine feeding, with optional micro‑vents to release trapped air and keep cartons compact. -

Core & Roll Specs:

Supplied on industry‑standard 3" cores with controlled roll diameters to match mainstream apparel and e‑commerce bagging equipment.

Related Products

-

Purpose‑Built Inner Protection: Clear poly inner bags designed for automated loading and sealing, protecting folded garments from dust, dirt, and snags during storage and transport.

-

Consistent Folding & Sizing: Optimized bag sizes and perforation spacing support standard folding boards and auto‑bagging equipment, delivering a neat, repeatable presentation in every order.

-

Scanner‑Friendly Clarity: High‑clarity films allow barcodes and size stickers to be scanned through the bag without opening, speeding up inbound receiving and outbound packing.

-

Paper‑Based Outer Packaging: Auto‑bagging compatible paper garment bags that replace traditional poly garment bags, combining sustainability with high‑speed e‑commerce fulfillment.

-

Brandable Surface: Smooth, printable paper surfaces support logos, care instructions, and campaign messages, turning every shipment into a branded unboxing experience.

-

Curbside‑Recyclable Experience: Designed to be easily recycled with household paper streams where facilities exist, helping apparel brands hit plastic‑reduction and ESG targets.

-

Plastic‑Free Packaging for Small Items: Semi‑transparent glassine bags sized for garments, accessories and branded inserts, keeping every piece together without using poly film.

-

Automation‑Ready Pick & Pack: Supplied as pre‑opened bags on rolls or fan‑fold in box, compatible with mainstream auto‑baggers for fast, low‑touch e‑commerce fulfillment.

-

Visible & Premium Presentation: Translucent paper lets products and barcodes show through while delivering a clean, minimalist, retail‑ready look for eco‑conscious brands.