Inside the Factory: How Vertical Integration Guarantees Drop-in Replacement Quality

- Johnson Chong

- 5 days ago

- 4 min read

Author: Adsure Manufacturing Team

Date: January 2026

Category: Technical Deep Dives / Quality & Certifications

Executive Summary

When you switch to a "drop-in replacement" supplier, the biggest fear is inconsistency. Will Batch #1 run perfectly, but Batch #5 jam your machine because they changed resin suppliers?

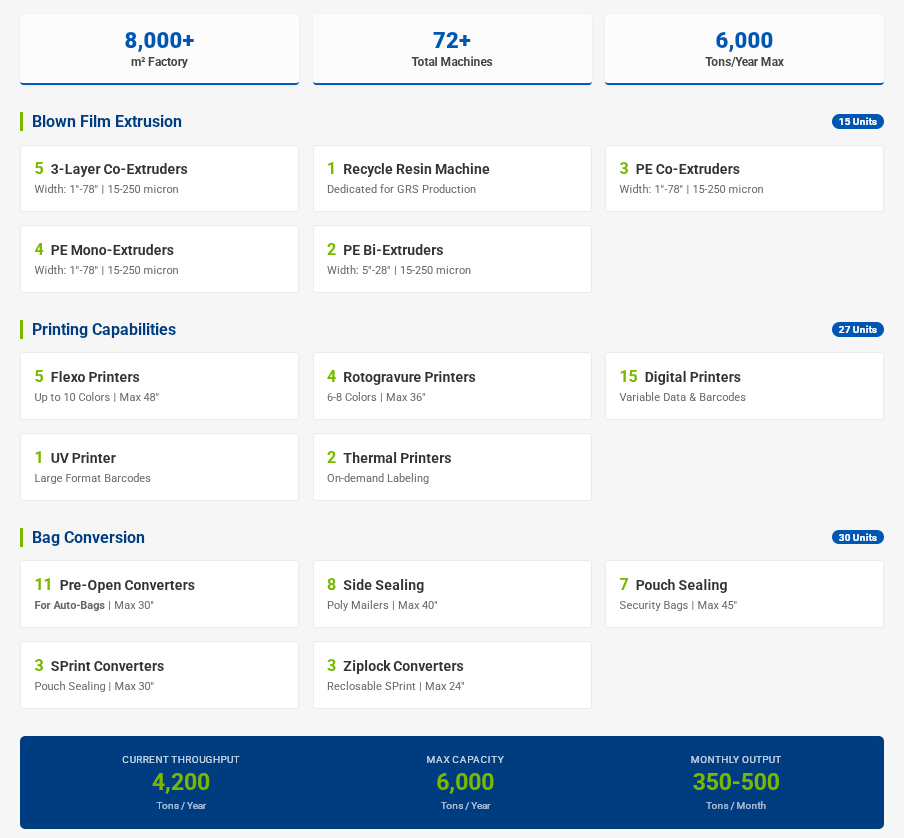

This is where vertically integrated manufacturers beat trading companies. At Adsure, we don't outsource film production or printing. From raw resin pellets to the final wound roll, every micron is controlled in-house across our 8,000m² facility with 72+ dedicated machines.

This article takes you inside our three-stage production system to show why control = consistency = zero surprises on your bagging line.

1. Stage One: Blown Film Extrusion – Engineering the "Feel" of the Bag

Why Film Matters for Autobag® Compatibility

Most people think "a bag is just a bag." Engineers know better. The way a bag feeds through an Autobag® AB 180 or Sharp™ SX depends on three invisible factors:

Coefficient of Friction (COF) – Too sticky, the bags won't separate. Too slippery, they won't grip the feed rollers.

Gauge Uniformity – If the film thickness varies by >5%, the optical sensor will misread the "top of bag."

Tensile Balance – Machine direction (MD) vs. transverse direction (TD) strength must match the machine's tear-off mechanism.

Our Extrusion Arsenal

5× Three-Layer Co-Extruders (Width: 1"-78" | 15-250 micron)

Why co-extrusion? The outer layers control slip (friction), while the core layer provides strength. This is critical for high-speed lines running >60 bags/min.

1× Dedicated GRS Recycled Resin Line

For customers facing EU plastic taxes or California SB 270, we can produce 100% Post-Consumer Recycled (PCR) film that still meets Autobag® tensile specs.

4× PE Mono-Extruders + 2× PE Bi-Extruders

These handle specialty films like VCI (anti-rust) or ESD (anti-static) for electronics packaging.

Key Advantage: Because we blow our own film, we can adjust the slip additive (erucamide) in real time based on your machine's humidity conditions. Trading companies can't do this—they buy commodity film and hope it works.

2. Stage Two: Printing Capabilities – From Bland to Brand

Why Pre-Printing Matters

Many factories assume "printing is just decoration." But for high-volume fulfillment centers, pre-printed bags eliminate a bottleneck. Instead of waiting for the thermal printer to print a logo + barcode (adding 0.5 seconds per bag), you can run pre-printed rolls at full machine speed and only print variable data (like serial numbers).

Our Print Fleet (27 Units Total)

5× Flexo Printers (Up to 10 Colors | Max 48" width)

Perfect for bold logos and solid color branding. Used by e-commerce clients who want their brand on every bag.

4× Rotogravure Printers (6-8 Colors | Max 36" width)

The "HD" option. Gravure delivers photo-realistic images and fine text (as small as 4pt). Ideal for retail packaging or pharmaceutical bags with complex regulatory text.

15× Digital Printers (Variable Data & Barcodes)

These allow us to print sequential numbers or unique QR codes directly during the bag-making process. No need for a separate labeling step.

1× UV Printer (Large Format Barcodes) + 2× Thermal Printers (On-demand Labeling)

Real-World Example:

A Tier-1 automotive supplier needed pre-opened VCI bags with:

A 6-color company logo

A unique lot number on each bag (printed sequentially)

A "Fragile" icon in 3 languages

With our integrated print + conversion line, we printed, cut, and perforated these in a single pass. An OEM supplier quoted this as "two separate vendors" (print house + converter), adding 3 weeks to the lead time.

3. Stage Three: Bag Conversion – The "Pre-Open" Secret

What Makes a Bag "Pre-Opened"?

Pre-opened bags on a roll have a unique mechanical design:

A perforation (tear line) between each bag.

A slit on the top that allows the machine's "jaw" to open the bag.

Precise registration marks so the machine knows where to seal.

If any of these is off by even 2mm, the bag will jam. This is why Autobag® charges a premium—they claim only their bags have the "right" specs.

We reverse-engineered those specs. And then made them better.

Our Conversion Lines (30 Units Total)

11× Pre-Open Converters (For Auto-Bags | Max 30" width)

These are dedicated to making rolls for Autobag®, Sharp™, and Pac Machinery™ systems. We run 3 shifts, 6 days/week.

Capacity: 6,000 tons/year max output. That's roughly 240 million bags/year.

8× Side Sealing Machines (Poly Mailers | Max 40")

For customers who need traditional side-seal poly bags (like Amazon-style bubble mailers).

7× Pouch Sealing Lines (Security Bags | Max 45")

Tamper-evident courier bags with peel-and-seal closures.

3× SPrint Converters + 3× Ziplock Converters

Specialty formats for retail or food packaging.

Key Advantage: With 11 pre-open lines, if one machine goes down for mainte

nance, we have 10 backups. Your order never gets delayed. OEM suppliers often have only 2-3 lines, so a breakdown means weeks of backlog.

4. The "3-Week Lead Time" Equation

Let's compare:

Scenario | OEM Supplier (Sealed Air) | Adsure (Vertical Integrated) |

Film Source | Must order from 3rd-party film mill (2-3 weeks) | In-house extrusion (Same day) |

Printing | Outsourced to converter (1-2 weeks) | In-house print line (Same pass) |

Conversion | Queue time (4-6 weeks) | Dedicated capacity (1 week) |

QC & Packing | 1 week | 3 days (In-line inspection) |

Total Lead Time | 8-12 weeks | 3-4 weeks |

When you control the entire chain, you eliminate the "waiting for the other guy" delays.

5. How This Protects Your Machine (And Your Warranty)

Some purchasing managers worry: "If I use a non-OEM bag and it damages my $50,000 Autobag® machine, am I screwed?"

Legal Answer: No. The Magnuson-Moss Warranty Act (U.S. federal law) prohibits equipment manufacturers from voiding warranties simply because you used third-party consumables—unless the consumable directly caused the damage.

Engineering Answer: Adsure bags won't damage your machine because:

Film Thickness Tolerance: ±3% (tighter than OEM's ±5%).

Perforation Strength: Tested to match OEM tear-off force (measured in Newtons).

Static Decay: Our anti-static additive reduces cling to <0.05 seconds (vs. 2 seconds for generic poly).

We've run 10,000-cycle jam tests (see our previous blog) to prove this.

Conclusion: Control = Consistency

When you buy from a trading company, you're trusting that they trust their suppliers. When you buy from Adsure, you're buying from the people who melt the resin, print the logo, and cut the perforation—all under one roof.

That's why our customers report <0.02% jam rates over millions of bags. That's why we can promise 3-week lead times. And that's why switching to Adsure isn't a risk—it's an upgrade.

Ready to See the Difference?

Request a Free Factory Audit Report (PDF) showing our equipment list, capacity breakdown, and QC protocols. Or request a Challenge Roll to test on your line.

Comments