OEM vs. Aftermarket Auto‑Packing Bags: How to Cut Film Cost Without Risking Your Bagger

- Johnson Chong

- Dec 10, 2025

- 6 min read

Updated: Jan 9

Author: Johnson Chong, CEO

CEO of Adsure Packaging Limited

Master's degree from the University of Warwick

30+ years of expertise in producing automated packaging bags

Helps operations teams choose consumables that match their bagging equipment.

Proven strategies to cut material waste, reduce downtime, and drive cost-effective efficiency across your packaging line.

【Length: 1,150 words | Estimated reading time: 5–6 min】

TL;DR – When Is It Safe to Leave OEM Bags?

OEM auto‑packing bags are predictable and low‑risk, but typically cost 20–40% more per bag than high‑quality aftermarket equivalents in industrial markets.

Reputable aftermarket pre‑opened bags are manufactured to the same core diameter, perforation pattern, and film gauges as OEM bags and are advertised as fully compatible with most Autobag‑style baggers.

The real risk is not "non‑OEM" itself, but bags that fall outside the machine's specifications: incorrect width, thickness, slip, or perforation can cause jams, poor seals, and downtime.

A structured three‑step process—lab sample check, low‑speed trial, then full‑speed A/B run—lets you validate aftermarket bags while keeping your line and warranty safe.Best for: operations already running Autobag / Sharp / similar baggers and feeling the pain of OEM film prices.

Why OEM Bags Feel "Safe" – And Expensive

Most automated bagging lines start life running OEM‑branded pre‑opened bags. The bags are engineered by the same company that built the machine, so dimensions, perforation pitch, film stiffness, and sealing window all fall well inside the equipment's comfort zone.

That peace of mind comes at a price. In many industrial consumables categories, OEM parts carry a premium of 20–60% over functionally equivalent aftermarket products, largely because the OEM controls the channel and bundles consumables with service. As bag volume grows into millions of pieces per year, even a few tenths of a cent per bag add up to five‑ or six‑figure annual deltas.

What "Aftermarket Auto‑Packing Bags" Actually Mean

In the auto‑packing world, aftermarket bags are typically pre‑opened bags on a roll or fan‑folded stacks produced by third‑party film converters. Leading suppliers design these bags specifically to match "Autobag‑style" or "Sharp‑style" equipment, using industry‑standard cores, consistent perforation, and thickness ranges of roughly 1.5–4.0 mil depending on the application.

Many of these products are explicitly marketed as compatible with "Autobag and most other automatic baggers" or "all standard automatic packaging equipment," emphasising that they follow the same dimensional and mechanical requirements as the OEM film. For you as a plant manager, the question is whether that compatibility claim holds up at your speed, with your product mix.

Cost and TCO: It's More Than Price per Bag

Typical Price Gap: OEM vs Aftermarket Bags

Published prices and distributor quotes across industrial parts categories suggest OEM consumables often run 20–40% higher than quality aftermarket equivalents, with some examples showing differentials above 60%. Auto‑packing bags follow the same pattern: OEM‑branded film commands a premium for branding, bundled support, and perceived safety.

On a bag that costs 4.0 cents from the OEM, a 25% reduction drops the unit price to 3.0 cents. At 5 million bags per year, that one‑cent difference equates to 50,000 USD in annual material savings, without touching labor, freight, or equipment utilization.

Total Cost of Ownership Factors

The right way to compare OEM and aftermarket bags is to look at total cost of ownership rather than unit price alone. Key elements include:

Bag price per thousand.

Changeover frequency and scrap during roll changes.

Jam rate and associated downtime minutes per shift.

Seal failure or bag burst rates and the cost of rework.For high-return categories, returnable auto-mailers can further optimize reverse logistics costs.

Lead time, safety stock requirements, and risk of stock‑outs.

If an aftermarket bag saves 25% on price but increases jams and rework enough to lose 20–30 minutes of production per shift, the net economics may be worse than staying with OEM, especially on high‑throughput lines.

Side‑by‑Side Comparison: OEM vs. Aftermarket Bags

What Actually Has to Match for Compatibility?

Critical Dimensional Parameters

Automatic baggers expect bags on industry‑standard cores and within a defined window of width, length, and thickness. Many third‑party pre‑opened bags use 1‑inch or 3‑inch cores and advertise seamless compatibility with standard automatic packaging equipment used for Autobag‑style machines.

From a mechanical point of view, you need to match:

Core diameter and roll outside diameter so the roll fits the spindle and unwind path.

Bag width and length within the range your machine and application are designed for.

Film thickness and stiffness that keep the bag open reliably at your speed.

Perforation pitch and quality to ensure clean separation and consistent indexing.

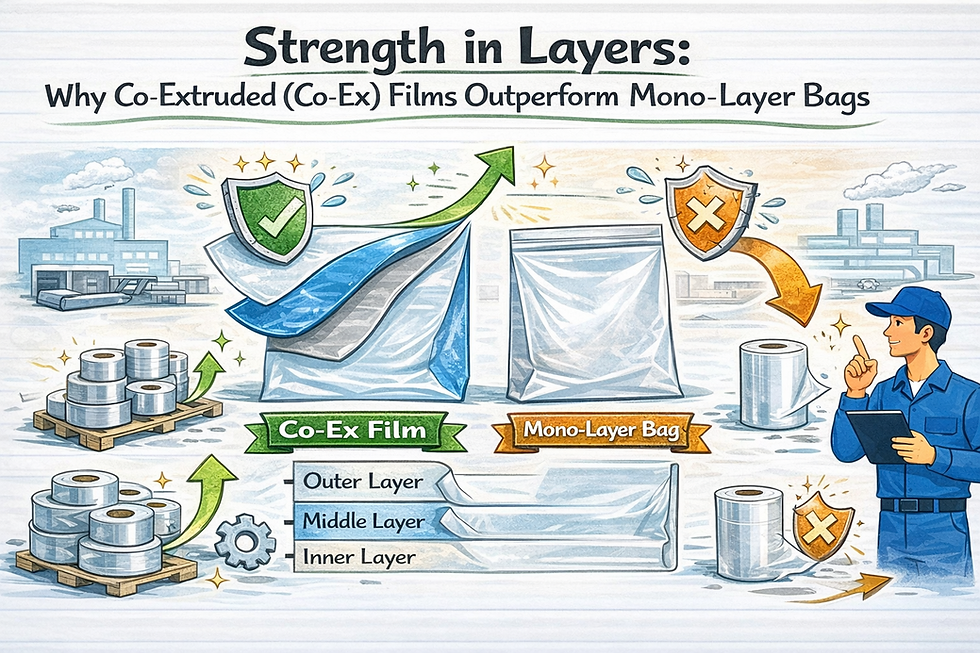

Film Properties and Sealing Window

Beyond geometry, film chemistry matters. Low‑density polyethylene films for auto‑packing need adequate tensile strength, the right coefficient of friction to feed cleanly, and a sealing window that matches the machine's heat and dwell settings. Suppliers that specialize in pre‑opened bags emphasise resin blends tuned for automated baggers and sometimes highlight proprietary resins to handle the stresses of high‑speed equipment.

OEM vs Aftermarket Bags:In practice, this means you should request technical data sheets that specify thickness, density, slip, and recommended sealing conditions for any aftermarket film you consider.

Three Scenarios: When to Stay OEM vs. Move to Aftermarket

Scenario 1: Regulated or High‑Risk Applications – Stay OEM or Qualify Slowly

If your line packs medical devices, sterile products, or safety‑critical components, the cost of a packaging failure can be extremely high. In these cases, OEM bags or thoroughly validated equivalents are usually the right choice. Any switch to aftermarket should go through a formal qualification process with documented testing and approvals.

Scenario 2: Standard E‑Commerce and Light Industrial – Aftermarket Is a Strong Candidate

For apparel, accessories, spare parts, and similar non‑regulated products, the business case for aftermarket bags is much stronger. Here, the downside risk of a packaging defect is mostly rework and re‑shipment, which can be effectively controlled by choosing proven aftermarket suppliers and running structured trials.

Scenario 3: Multi‑Line, High‑Volume Sites – Use a Dual‑Source Strategy

Large sites with several baggers often adopt a dual‑source model:

OEM bags as a reference and backup, plus one or two qualified aftermarket suppliers. This structure reduces price risk, avoids over‑dependence on a single brand, and provides flexibility if demand spikes or supply disruptions occur.

A Practical Three‑Step Validation Process

Step 1 – Desk Check and Sample Review

Start by comparing the aftermarket supplier's technical data sheets to your current OEM bags. Confirm width, length, thickness, core size, and any special features such as vent holes or printed warnings. Request a small number of sample rolls or fan‑fold stacks for initial testing.

Step 2 – Slow‑Speed Trial on One Line

Load the sample on a single bagger and run at a conservative speed with a representative product mix. Track jam counts, registration accuracy, seal appearance, and any unusual machine alarms over a defined number of bags. If possible, keep the OEM settings unchanged initially to see how the new film behaves under your standard conditions.

Step 3 – Full‑Speed A/B Test and Cost Analysis

Once the slow‑speed trial looks stable, increase to your normal line speed and run an A/B test: OEM film for a set number of hours, then aftermarket film for the same duration. Capture data for throughput, downtime minutes, scrap, and rework. Combine those performance metrics with the price per bag to calculate a true cost per good pack for each option.

Tip: Treat the validation run as an engineering experiment. Use simple checklists for operators to log jams and issues, and involve maintenance so they can confirm that the film does not cause abnormal wear or residue on key components.

Common Questions About Using Aftermarket Bags(FAQs)

Q1:Will using non‑OEM bags void my machine warranty?

Warranty terms vary by manufacturer, so the only definitive answer is in your specific contract. Many equipment suppliers discourage non‑OEM consumables but focus warranty coverage on defects in materials and workmanship. As long as aftermarket bags are within specification and do not cause damage, some users successfully run them without warranty issues, but it is wise to clarify this with your OEM or distributor before making a change.[Protected under the Magnuson-Moss Warranty Act]

Q2:Are aftermarket bags more likely to jam or cause bad seals?

Poorly made bags can definitely increase jams and sealing problems. However, bags engineered specifically for automatic baggers, using appropriate resins and precise perforation and sealing, are designed to feed and seal as reliably as OEM film. The difference comes down to supplier quality and whether the film is within the machine's recommended envelope.

Q3:How much volume do I need for aftermarket to make sense?

Even at a few hundred thousand bags per year, a 20–30% reduction in unit price can offset the time needed for validation. At multi‑million bag volumes, the savings rapidly grow to tens or hundreds of thousands of dollars annually, which easily justifies engineering effort and a structured trial program.

Q4:What should I demand from an aftermarket supplier?

At a minimum, ask for detailed specifications, samples for testing, traceability on resin batches, and consistent lead times. Many better suppliers also offer custom printing, recycled content options, and support from application engineers who understand automatic baggers, not just film extrusion.

Q5:Where Adsure‑Style Aftermarket Bags Fit In?

For operations already running Autobag, Sharp, or similar equipment, high‑quality aftermarket pre‑opened bags provide a way to separate machine choice from film choice. By matching OEM dimensions and film behaviour while offering more flexible pricing and customization, they create commercial leverage and a path to material savings without touching your hardware.

Q6:What’s the lowest-risk way to reduce packaging cost per order without changing equipment?

Combine a disciplined validation process with clear communication with your machine OEM, then switch part of your volume to compatible aftermarket bags—especially if you’re already consuming millions of bags per year.

Comments