What’s the Difference Between PCR and PIR? A Guide to Choosing the Right Recycled Materials

- Johnson Chong

- Jan 4

- 4 min read

Updated: Jan 6

As global sustainability mandates tighten—from the UK Plastic Packaging Tax to EU directives—"Recycled Content" is no longer just a marketing buzzword; it’s a procurement requirement. But when you request "recycled bags" for your automated packaging line, not all materials are created equal.

The two main contenders are PCR (Post-Consumer Recycled) and PIR (Post-Industrial Recycled).

For a procurement manager, choosing the wrong resin can mean failing a compliance audit (expensive) or facing a production line full of broken bags (even more expensive). As a GRS 4.0 certified manufacturer, Adsure is here to break down the science and help you choose the right film for your high-speed auto-baggers.

Quick Verdict: Which One Should You Choose?

Choose PIR (Post-Industrial) If: You need crystal-clear transparency (e.g., apparel display), maximum strength, and a lower price point.

Choose PCR (Post-Consumer) If: You need to comply with Plastic Taxes (UK/EU require 30%+ PCR), verify GRS certification, or tell a "waste-to-value" sustainability story to consumers.

The Adsure Solution: Our 3-Layer Co-Ex films allow high PCR content bags to run flawlessly on automated machines without jamming.

1. The Difference Between PCR and PIR Recycled Materials

To predict performance, you must understand where the resin comes from.

What is PIR (Post-Industrial Recycled)?

The Source: Also known as "Pre-Consumer," this material comes from factory waste. Think of the edge trims cut off during bag making, or startup waste from an extrusion line.

The Quality: Because this plastic never left the factory floor, it is clean, free of contaminants (like ink or paper labels), and has minimal heat history.

The Analogy: It’s like cookie dough trimmings. When you cut out cookies, you take the leftover dough and roll it back up to make more. It is essentially as good as fresh dough.

What is PCR (Post-Consumer Recycled)?

The Source: This is plastic that has been "out in the wild." It comes from used milk jugs, shopping bags, and shrink wrap that consumers threw in a recycling bin. It is collected, washed, shredded, and pelletized.

The Quality: It is naturally more variable. It may contain microscopic traces of inks, other polymers, or "gels" (tiny unmelted particles).

The Analogy: This is like breadcrumbs made from old bread. It has a "previous life" that slightly changes its texture, color, and structural integrity.

Comparison table showing difference between PCR and PIR packaging specs

2. The Performance Battle: Clarity, Strength & Compliance

When running these films on high-speed auto-baggers (like Autobag® or Sharp™ systems), the differences are stark.

Head-to-Head Comparison Table

Feature | PIR (Post-Industrial) | PCR (Post-Consumer) |

|---|---|---|

Clarity | High. Almost indistinguishable from virgin material. | Lower. Often slightly cloudy, grey, or has visible "gels" (tiny dots). |

Strength | Excellent. Retains 95-99% of virgin tensile strength. | Good (if engineered). Can be brittle if not blended correctly. |

Whiteness | Pure White. | Off-White / Creamy (unless heavily pigmented). |

Cost | Lower than Virgin ($). | Often Higher than Virgin ($$$) due to collection/cleaning costs. |

Plastic Tax Exempt? | No (Usually not counted as "recycled" for tax purposes). | Yes (UK/EU recognize PCR for tax exemptions). |

Manufacturer’s Insight: Many brands want PCR for the story but dislike the visual "defects" (gels/dots). We tell our clients: Embrace the imperfection. Those tiny dots are proof to your customer that the bag is truly recycled.

3. The Manufacturing Challenge: Solving "PCR Fragility"

The biggest fear with PCR is that it will snap or melt unevenly on an automated packing line. High percentages of PCR (e.g., 50% or 100%) can have a fluctuating "Melt Flow Index," leading to weak seals or zipper failures.

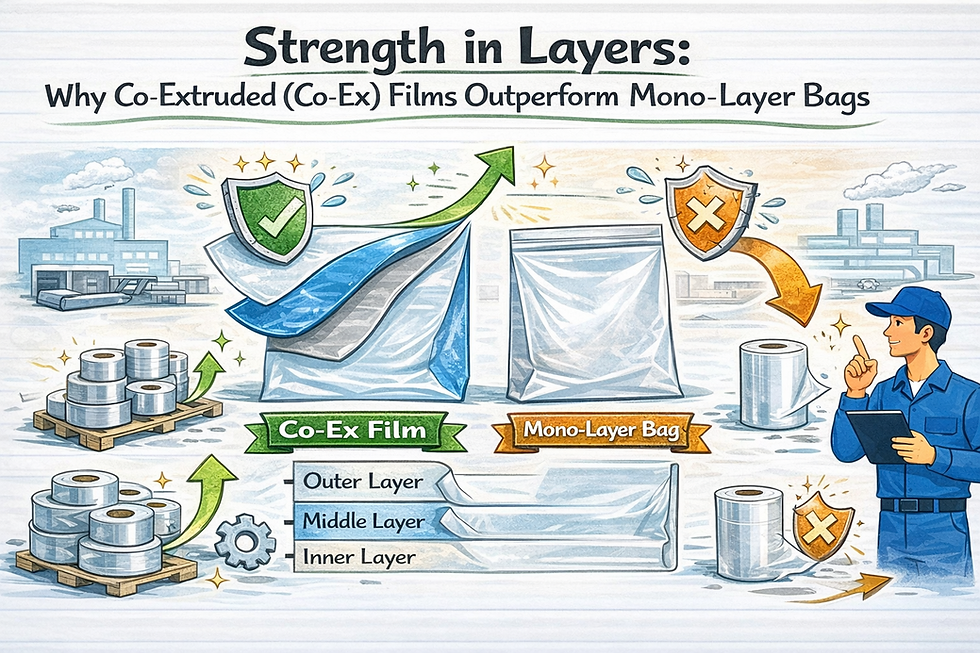

How Adsure Solves This: 3-Layer Co-Extrusion Technology

We don't just mix the plastic; we structure it using an ABA or ABC co-extrusion process:

Outer Layer (Skin): Virgin or PIR Resin. Provides a smooth, high-slip surface for printing and easy machine feeding.

Core Layer (Middle): High-Content PCR. This layer does the heavy lifting for sustainability compliance (e.g., 50%+).

Inner Layer (Skin): Special Slip-Agent Blend. Ensures the bag opens instantly without jamming the air-opening mechanism.

Result: You get a bag that is legally "Recycled" but runs like a "Virgin" bag.

4. The "Greenwashing" Trap: Why GRS Certification is Non-Negotiable

Anyone can claim a bag is "recycled." Proving it to a government auditor is harder.

Adsure holds the Global Recycled Standard (GRS 4.0) certification. This is critical for two reasons:

Traceability: We track the recycled resin from the recycling plant all the way to your specific roll of bags.

Transaction Certificates (TC): For every shipment, we can issue a legal TC document. This is the only proof European customs or tax authorities will accept to waive plastic packaging taxes.

Warning: If your supplier cannot provide a TC, you are likely not buying certified recycled plastic, and you may still be liable for taxes.

5. FAQ: Common Questions About Recycled Auto-Bags

Q: Can I use PCR bags for food packaging?

A: Generally, No, unless the PCR resin is specifically FDA-approved for food contact (which is rare and expensive for poly bags). For direct food contact, we recommend Virgin material or certified PIR.

Q: Will switching to 50% PCR require me to change my machine settings?

A: Usually, yes. PCR absorbs heat differently than virgin plastic. You may need to slightly increase your seal temperature or dwell time. Adsure provides a Technical Settings Guide with every order to help you calibrate.

Q: What is the minimum PCR % to avoid the UK Plastic Tax?

A: Currently, packaging must contain at least 30% recycled content (specifically PCR in most interpretations) to be exempt from the tax. Adsure’s standard PCR blends (30%, 50%, 100%) are designed to meet this threshold.

Conclusion & Call to Action

Don't guess with sustainability. Whether you need the pristine clarity of PIR for retail display or the strict regulatory compliance of PCR for global shipping, Adsure engineers the film to run flawlessly on your equipment.

See the Difference Yourself:

[Request our "Sustainability Sample Kit" today.]

We will send you physical samples of 30%, 50%, and 100% PCR bags so you can compare the clarity and seal strength against standard virgin films.

Comments