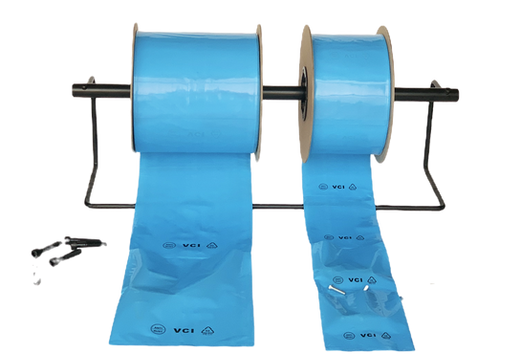

ADSURE® Standard VCI Auto-Bagging

Safeguard metal components from corrosion and rust throughout your supply chain with cost-effective, automated packaging bags.

-

Active Corrosion Prevention

VCI chemicals prevent rust by forming a protective layer on metal surfaces. -

Eliminates Prep Labor

Replaces messy rust-preventatives with dry packaging for immediate assembly. -

Brand Value Elevation

Customizable printing enhances product presentation and brand visibility. -

Clear Identification

Translucent film allows visual inspection and barcode scanning without breaking the seal.

Engineered for seamless integration with your existing auto-baggers. Our Standard VCI films feature precise optical registration marks and tension control, ensuring zero-error feeding on mainstream hardware kitting lines without calibration headaches.

-

Autobag®: AB 180, 500, 550 & 850S Series (Rolls)

-

Sharp™: SX™ & MAX-PRO™ Series (Rolls & Fan-Fold)

-

Pac Machinery™: Rollbag™ R1285 & R3200 Series (Rolls & Tubing)

Reliable Corrosion Protection for Automated Hardware Fulfillment

What are Adsure® VCI Auto-Bagging Consumables?

They are precision-engineered, pre-opened bags on a roll, specifically formulated with Volatile Corrosion Inhibitor (VCI) technology to meet industrial export standards. By integrating active anti-rust chemistry directly into the film, you gain robust protection against oxidation for ferrous metals (like iron, steel, and cast iron) during storage and transport, while significantly reducing labor costs by eliminating the need for messy oils or greases.

How to use our Auto-Bagging Films?

Designed for "drop-in" compatibility, simply load our rolls onto your existing Autobag®, Sharp™, or PAC Machinery™ automated baggers. Our films feature precise optimized slip levels, allowing your equipment to detect, open, and seal the bags seamlessly without requiring machine recalibration or hardware modification. [Request a compatibility test roll] to verify the fit on your specific production line.

Specification

VCI Performance & Mechanical Properties

Parameter | Specification Range | Test Method / Notes |

|---|---|---|

Material Base | Co-extruded LDPE with VCI Additive | High-strength blend |

Appearance/Tint | Translucent Yellow or Blue | Allows barcode scanning |

Corrosion Protection | Ferrous Metals (Steel, Iron, Cast Iron),

Non-ferrous Metals (Copper, Aluminum) | Active VCI Chemistry |

Protection Duration | Up to 24 Months (Storage) / 6-12 Months (Transit) | Depends on seal integrity |

Tensile Strength | > 2800 psi (MD) / > 2400 psi (TD) | ASTM D882 |

Elongation at Break | > 450% | ASTM D882 |

Printability | Thermal Transfer Treated | Crisp barcode printing |

Option

Physical & Roll Dimensions

Parameter | Specification Range | Compatibility Notes |

|---|---|---|

Film Thickness | 2.0 mil -4.0 mil (50-100 micron) | Standard is 3 mil for Hardware |

Bag Width (Opening) | 2" to 36" (50mm - 914mm) | Fits Autobag 500/850S & Sharp |

2" to 72" (50mm - 1829mm) | 2" to 72" (50mm - 1829mm) | Customizable perforation |

Core Size (I.D.) | 3" (76mm) Industry Standard | Matches OEM Spindles |

Roll Outer Dia. (O.D.) | Up to 10" (254mm) or Custom | Optimized for long-run changes |

Perforation Type | Horizontal (Standard) or Vertical | Clean-tear technology |

Venting Options | Pinhole / Round / Flutter | For air evacuation |

Special Feature

-

Active VCI Chemistry: Impregnated corrosion inhibitors release protective vapors to form a molecular rust-shield on ferrous metals.

-

Translucent Identification: Available in Yellow or Blue tints to allow barcode scanning and visual inspection without breaking the sealed protection.

-

Oil-Free Packaging: Dry packaging technology eliminates the need for greasing parts or cleaning them before use, streamlining assembly.

-

Supply Flexibility: Available in Pre-Opened Rolls (for Autobag®) or Fan-Fold in Box (for Sharp™ high-speed continuous run).

Structural Options

-

Custom Venting: Pinhole, flutter, or round vents to evacuate trapped air for tighter packing and reduced shipping volume.

-

Reinforced Headers: Thickened header areas to support heavy hardware weights or accommodate Euro-Slots for retail display.

-

Easy-Open Perforations: Vertical or horizontal tear lines to allow end-users to open heavy-duty bags without cutting tools.

-

Heavy-Gauge Films: Film thickness options up to 4mil+ to provide extreme puncture resistance against sharp threads or points.

Related Products

-

Component Isolation: Internal seals create 2, 3, or 4 pockets within one bag to physically separate parts, preventing abrasion and scratching.

-

Zero Kitting Error: Guarantees all required pieces are present and organized, significantly reducing assembly errors and customer returns for missing components.

-

Automation Optimization: Designed for use with automated bowl feeders and counters, converting manual, complex kitting into a high-speed automated process.

-

Puncture Proof: 5-layer co-extruded Nylon/PE structure offers 3x the tensile strength of standard poly, making it virtually indestructible against sharp screws, drill bits, and metal stampings.

-

Oil & Oxygen Barrier: Locks in grease for lubricated automotive parts while blocking oxygen and odors, preventing leakage and ensuring product integrity during long-term storage.

-

Jam-Free Feeding: Engineered with a proprietary "Lay-Flat" formulation to eliminate curling and static, ensuring high-speed, uninterrupted performance on Autobag® and Sharp® baggers.

-

Enhanced User Experience: Includes a robust die-cut handle for easy carrying, adding perceived value for bulk orders or Ship-from-Store initiatives.

-

Heavy Product Handling: The handle is integrated into the reinforced header, providing durability when carrying dense kits, large filters, or apparel items.

-

Automated Application: Pre-opened bags on a roll format allow the bagger to seal the bottom while automatically presenting the handle feature at the top.

-

Retail-Ready Finish: Features a reinforced header with a precision Euro-Slot hole for immediate use on retail peg hooks.

-

High-Fidelity Branding: Supports 10-Color Rotogravure Printing for detailed logos, instructions, and vibrant product identification.

-

Simplified Supply Chain: Eliminates manual re-packaging or adding hang-tags at the final distribution center or store.

_edited_pn.png)